Description

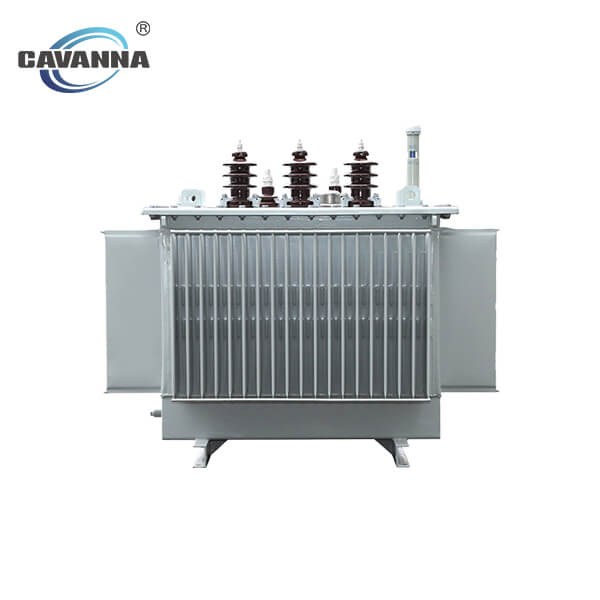

Distribution transformers oil-immersed with power rating from 25 to 2500 kVA and Voltage 6-36/0,4 (0.23)kV. In 50/60 Hz power transmission and distribution system for power supply and lighting in industrial and agricultural field. Distribution transformers are produced with nominal Voltage in primary winding 6 up to 36 kV. Nominal Voltage in secondary winding is 0,4 or 0,23 kV. Scheme and connection group of windings U/Un-0 or D/Un-11, etc. . On the customer demand it is possible to make transformers with different connection of the Voltage s and other construction solution. Regulating the Voltage is made as a result of moving the switch, by the transformer detached from the net both high (HV) and low (LV) Voltages.

The Voltage is being regulated on the side of HV for ±2×2,5% value from nominal value. Exterior introductions HV and LV are removable and passers-by are made from china insulators. At great current 1000 A and more on the hard core current are contact clamps screwed properly with the spatula which connecting the track or the cable attachment assures. The expandability of oil assures appropriate works of the transformer at different weather conditions and fluctuations of the temperature. The dehumidifier is installed to provide dry air in transformer.

For measuring the temperature of upper layers of oil on the casing a thermometer is installed. Transformers with power rating from 400 to 2500 kVA are occupied with wells to install in base.

1. Energy saved :

Compared with old type S7, no-load loss decreases 10.25% averagely and on-load current decreases 37.9%, which means 18.39% operation cost is reduced.

2. Long-term reliable service life:

Fully enclosed transformer tank and rim shall be bolted together or welded firmly. Isolation between oil and air keeps insulation away from moisture, which lowers insulation aging and improves service life.

3. Free from untanking:

Free from untanking before operation, so its cost is saved.

4. Free from maintenance

5. Low noise:

Impacted structure in design, new material and new technology adopted and low noise.

6. Small size and artistic appearance:

Owing to the corrugated plate used for radiation, oil volume is changed by adjustment and compensation through expansion and shrinkage of corrugated plate when the temperature of oil is changed. Corrugated tank is small size in good looking.

Compared with old type S7, no-load loss decreases 10.25% averagely and on-load current decreases 37.9%, which means 18.39% operation cost is reduced.

2. Long-term reliable service life:

Fully enclosed transformer tank and rim shall be bolted together or welded firmly. Isolation between oil and air keeps insulation away from moisture, which lowers insulation aging and improves service life.

3. Free from untanking:

Free from untanking before operation, so its cost is saved.

4. Free from maintenance

5. Low noise:

Impacted structure in design, new material and new technology adopted and low noise.

6. Small size and artistic appearance:

Owing to the corrugated plate used for radiation, oil volume is changed by adjustment and compensation through expansion and shrinkage of corrugated plate when the temperature of oil is changed. Corrugated tank is small size in good looking.

Specifications

Technical Information

| Rated Capacity(KVA) | Rated Voltage(KV) | Vector Group | Impedance(%) | No-load loss/Load loss(KW) | No-load Current(%) |

| 10 | (HV)11/10.5/10/6.3/6 (LV)0.4/0.69 | Yyn0, Dyn11 | 4 | 0.065/0.4 | 3.5 |

| 20 | 0.08/0.52 | 3 | |||

| 30 | 0.1/0.63(0.6) | 2.3 | |||

| 50 | 0.13/0.91(0.87) | 2 | |||

| 63 | 0.15/1.09(1.04) | 1.9 | |||

| 80 | 0.18/1.31(1.25) | 1.9 | |||

| 100 | 0.2/1.58(1.5) | 1.8 | |||

| 125 | 0.24/1.89(1.8) | 1.7 | |||

| 160 | 0.28/2.31(2.2) | 1.6 | |||

| 200 | 0.34/2.73(2.6) | 1.5 | |||

| 250 | 0.4/3.2(3.05) | 1.4 | |||

| 315 | 0.48/3.83(3.65) | 1.4 | |||

| 400 | 0.57/4.52(4.3) | 1.3 | |||

| 500 | 0.68/5.41(5.15) | 1.2 | |||

| 630 | 4.5 | 0.81/6.2 | 1.1 | ||

| 800 | 0.96/7.5 | 1 | |||

| 1000 | 1.15/10.3 | 1 | |||

| 1250 | 1.36/12.0 | 0.9 | |||

| 1600 | 1.64/14.5 | 0.8 | |||

| 2000 | 1.96/19.8 | 0.8 | |||

| 2500 | 2.31/23.0 | 0.7 |

Note: High-pressure tap range: ± 5% or ± 2 × 2.5%; Frequency: 50HZ