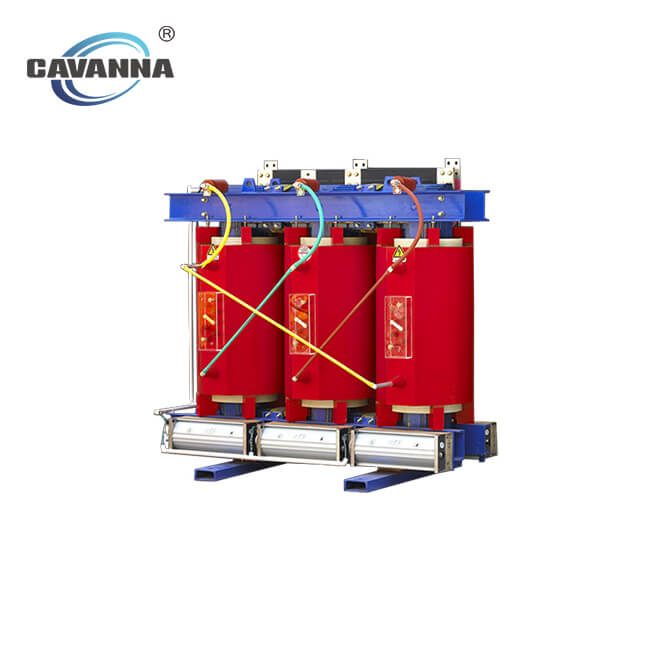

Description

Dry type transformers has been cast with epoxy resin, both cooling by fan and natural (ANAF), thermal class F , three-phase, 50/60 Hz.

For indoor use.

Protection Class: IP00 or IP2X(with enclosure housing)

Features

Since epoxy resin is a non-flammable, flame-retardant, self-extinguishing solid insulating material, safe and clean, epoxy resin cast dry-type transformers are oil-free, non-flammable, and have low operating loss, strong short-circuit resistance, less maintenance work, high working efficiency, small volume and low noise. It is often used in places with high performance requirements such as fire prevention and explosion protection, and has the following practical characteristics:

1.It is safe,fireproof,pollution-free,and can be directly operated in the load center;

2.High mechanical strength,strong short-circuit resistance,small partial discharge,good thermal stability,high reliability and long service life;

3.Low loss,low noise,obvious energy saving effect,maintenance-free;

4.Good heat disspation performance ,and capacity operation can be increased in short time when forced air cooling;

5.Good moisture resistance;

6.Dry-type transformers can be equipped with a complete temperature detection and protection system.Using intelligent signal temperature control system, it can automatically detect and display the respective operating temperatures of the three-phase windings, can automatically start and stop the fan, and have functions such as alarms and trips. IS485 communication interface can be installed to realize wireless detection and intelligent management.

7.Small size, light weight, less space and low installation cost.

Instructions for use

Common power ratings:

25(30),50(40),63,80(75),100,160,200,250,400,500,630,800,1000,1250,1600,2000,2500,3150kVA.

This transformer is designed for voltages of ≤ 36 kV. Specific figures are not given for this parameter because of the wide variety of voltages used. Transformers can be supplied on demand to run at two different primary voltages, the shift between these input voltages has two.

Basic alternatives:

• with no load and no applied voltage to changing primary terminals.

The secondary voltage under no load is allocated at 400V, 415V, 433V, though other voltages can be supplied on demand.

When usage requires two voltages, transformers with two simultaneous voltages can be supplied. In this case the no-load voltages are set to 400V(230V),415V(240V),433V(230V) .

The connections normally used are as follows:

• For rated power levels of 160 kVA or less: Yyn0

• For rated power levels over 160 kVA: Dyn11.

• Dyn5, Yd11 and others can customaized.